Wellhead Equipment

PRODUCTS DETAILS

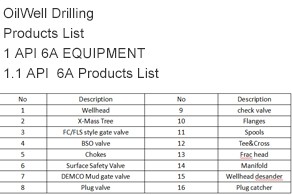

OilWell

Drilling

Products List

1 API 6A EQUIPMENT

1.1 API 6A Products List

No | Description | No | Description |

1 | Wellhead | 9 | check valve |

2 | X-Mass Tree | 10 | Flanges |

3 | FC/FLS style gate valve | 11 | Spools |

4 | BSO valve | 12 | Tee&Cross |

5 | Chokes | 13 | Frac head |

6 | Surface Safety Valve | 14 | Manifold |

7 | DEMCO Mud gate valve | 15 | Wellhead desander |

8 | Plug valve | 16 | Plug catcher |

API 16A&16C&16D Products List

No Description

1 BOP

2 Rigid choke and kill lines

3 BOP control station

1.2 API 6A Specification

1.2.1 Size

No | Size | No | Size |

1 | 1-13/16" | 10 | 11' |

2 | 2-1/16" | 11 | 13-5/8" |

3 | 2-9/16" | 12 | 16-3/4" |

4 | 3-1/8" | 13 | 18-3/4" |

5 | 3-1/16" | 14 | 20-3/4" |

6 | 4-1/16" | 1 | 21-1/4" |

7 | 5-1/8" | 16 | 26-3/4" |

8 | 7-1/16" | 17 | 30" |

9 | 9" | 18 |

1.2.2 Pressure

Ratings

No | PSI | Mpa |

1 | 2000 | 13 8 |

2 | 3000 | 20.7 |

3 | 5000 | 34.5 |

4 | 10000 | 69.0 |

5 | 15000 | 103.5 |

6 | 20000 | 138.0 |

1.2.3 Temperature

Ratings

Temperature Class | Temperature Ratings | |||

℃ | ℉ | |||

Min | Max | Min | Max | |

K | -60 | 82 | -75 | 180 |

L | -46 | 82 | -50 | 180 |

N | -46 | 60 | -50 | 140 |

P | -29 | 82 | -20 | 180 |

S | -18 | 60 | 0 | 140 |

T | -18 | 82 | 0 | 180 |

U | -18 | 121 | 0 | 250 |

V | 2 | 121 | 35 | 250 |

Note: Minimum temperature is the lowest ambient temperature to which the equipment can be subjected.Maximum temperature is the highest temperature of the fluid that can directly contact equipment Design for temperature ratings above 121℃(250 "F), e.g. classifications X and Y (see Table G.1),shall account for the effects of temperature on material strength (see Annex G for guidelines).

1.2.4 Material Classes

Material Class | Body,Bonnet,End and outlet connectors | Mandrel hangers,valve bore sealing mechanisms,choke trim,and stems | |

AA | General Service | Carbon or low-alloy steel,or stainless steel or CRA d | Carbon or low-alloy steel,or stainless steel or CRA d |

BB | General Service | Carbon or low-alloy steel, or stainless steel or CRA d | Carbon or low-alloy steel,or stainless steel or CRA d |

CC | General Service | stainless steel or CRA d | stainless steel or CRA d |

DD | Sour Service | Carbon or low-alloy steel,or CRA b,d | Carbon or low-alloy steel,or CRA b,d |

EE | Sour Service | Carbon or low-alloy steel,or CRA b,d | stainless steel or CRA b,d |

FF | Sour Service | stainless steel or CRA b,d | stainless steel or CRA b,d |

HH | Sour Service | CRA b,c,d | CRA b,c,d |

FOOTNOTES: a As defined by NACE MRO175/ISO 15156 | |||

1.2.5 Product Specification Level

Min PSL

Material Class

| Rated Working Pressure | |||||

13.8 MPa (2000 psi) | 20.7 MPa (3000 psi) | 34.5 MPa (5000 psi) | 69.0 MPa (10,000 psi) | 103.5 MPa (15,000 psi) | 138.0 MPa (20,000 psi) | |

AA.BB.CC | PSL 1 | PSL 1 | PSL 1 | PSL 2 | PSL 2 | PSL 3 |

DD,EE,FF | PSL 1 | PSL 1 | PSL 1 | PSL 2 | PSL 3 | PSL 3 |

HH, ZZ | PSL 3 | PSL 3 | PSL 3 | PSL 3 | PSL 3 | PSL 4 |

Copyright ©Dalian Botong Processed Metals LLC All Rights Reserved Powered by:www.ieaseweb.com